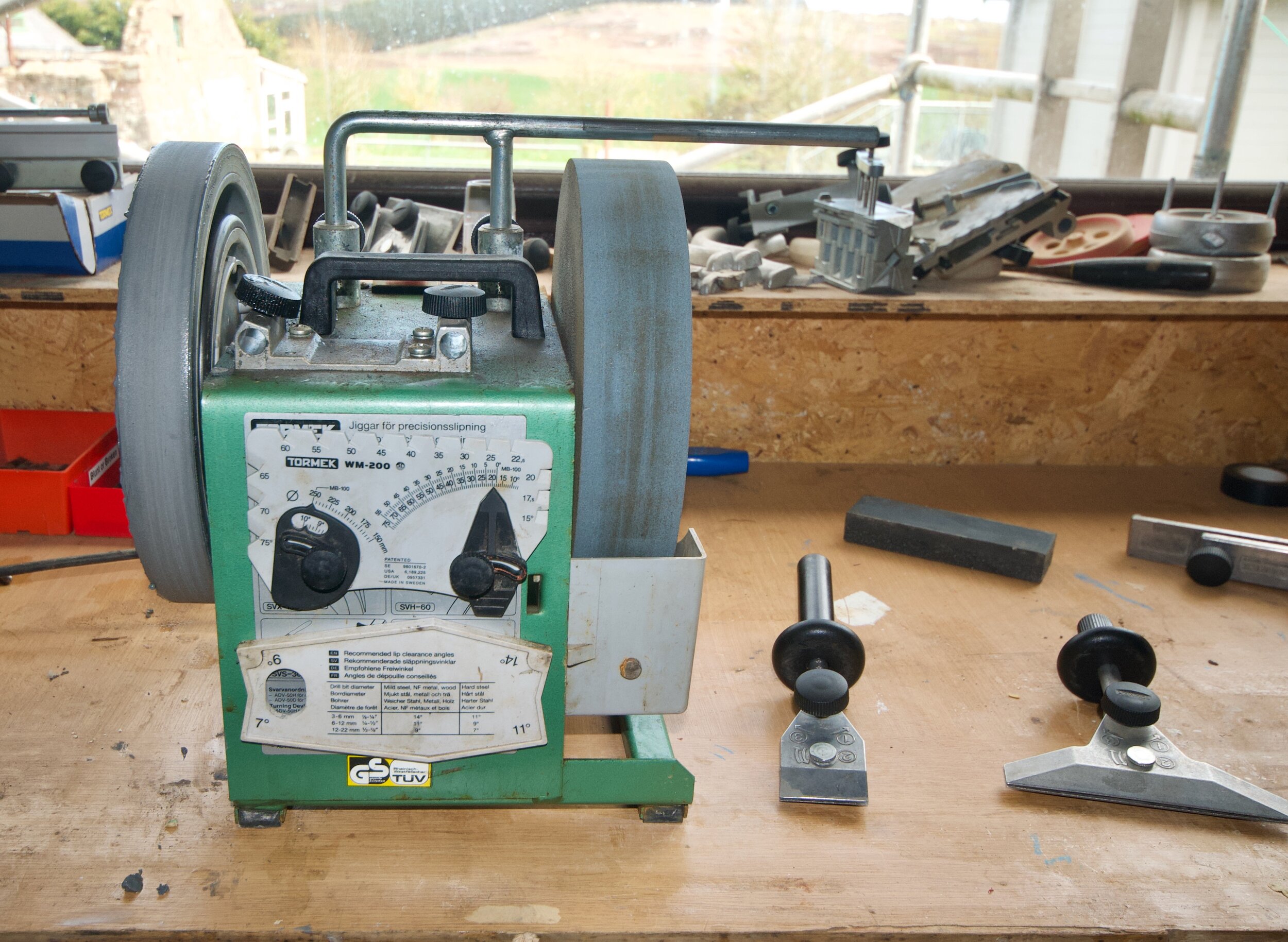

The Tormek

The machine that kicked it all off.

It is a Swedish built machine that spins a large abrasive wheel in a trough of water. The water provides cooling to the tools being ground as well as washing away removed material. There is a set of gudie rails fitted to the machine frame that allow various jigs to be used to maintain accuracy. It is a popular machine with professionals and amateurs in many different fields. As such there is a wide variety of different wheels and jogs produced both by Tormek themselves as well as different 3rd parties.

To the left hand side of the machine there is a composite wheel which can be used in a smilier manner to a leather strop allowing polishing compounds to be used for polishing and removing the burr from grinding

Read more about the Tormek story HERE

Originally purchased back before Barras Blades was even a thing. It was bought 2nd hand so I could use it for keeping my wife’s kitchen knifes nice and sharp as well as for sharpening some tools around the workshop. Slowly but surely I bought more tooling and jigs for it.

The Tormek 2000

The machine sitting in its normal place along with the collection of jigs i have for it

The knife jigs

The go to jigs for professional knife sharpeners the SVM-45 and the SVM-140 which allow a consistent grinder angle to be achieved on the knife edge

Square edge jig

The original SE-76 which is used for chisels and plane irons which again allows for a consistent and repeatable angle

The scissor jig

The SVX-150 jig which is used for larger scissors such as kitchen and dress making scissors as well as pinking shears

The twist drill jib

This is probably the jig I use the most for myself the DBS-22 jib which is used for resharpening twist drills. As I do alot of metal work this is massively useful as it allows an accurate and repeatable 4 facet grind on normal twist drills. Being able to keep drills razor sharp allows for more accurate and easier drilling.

Read more about it HERE